I joist dimensions in modern construction

I joist dimensions play a crucial role in construction, affecting strength, span, and stability in floor and roof systems for safe structural design.

I-joists have an “I” shape. They include a top and bottom flange and a vertical web. The flanges are often made from laminated or solid wood. The web is usually made from OSB or plywood.

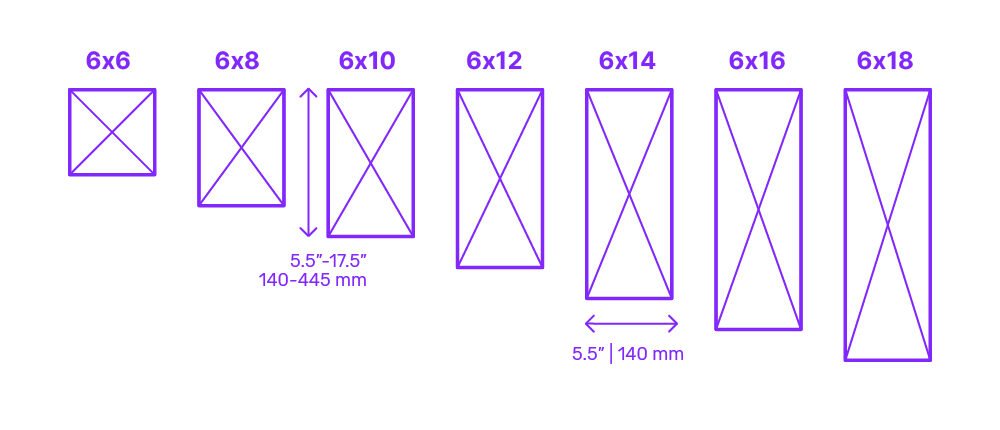

Standard flange widths are 1½ to 3½ inches. The depth of the web forms the main structural size. I-joists come in different series with codes like “TJI 210.” This code shows size and strength. Each model has a specific depth and performance rating.

What Is the Typical Depth Range for Residential I Joists?

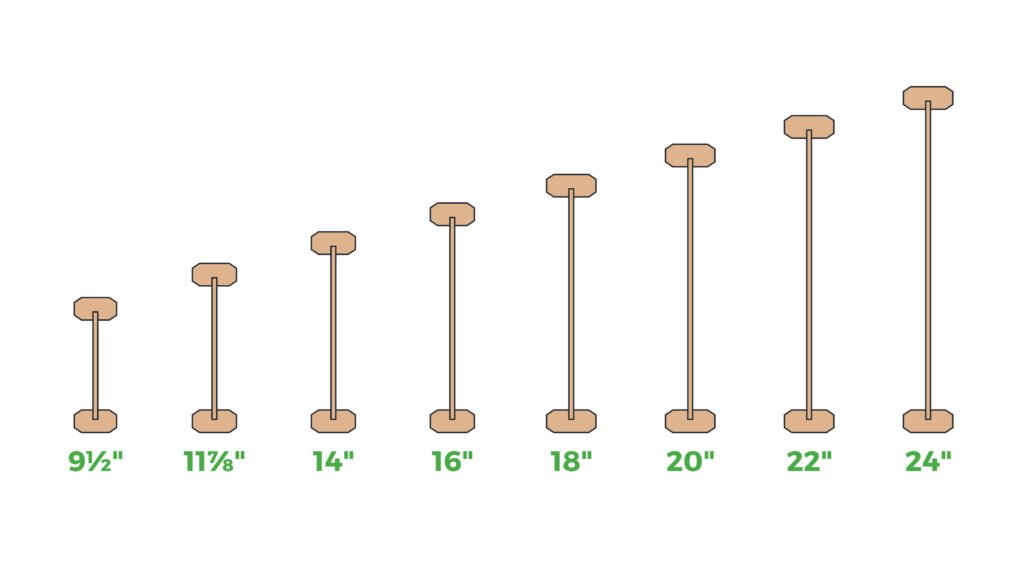

In residential construction, the depth of I-joists commonly ranges from 9½ inches to 16 inches. The most widely used depths for standard floor joist applications include:

- 9½ inches – suitable for short spans or closely spaced joists.

- 11⅞ inches – one of the most popular choices for residential flooring due to its balance of strength and depth.

- 14-inch and 16-inch I-joists for longer spans or when they need deeper cavities for HVAC, plumbing, or insulation systems.

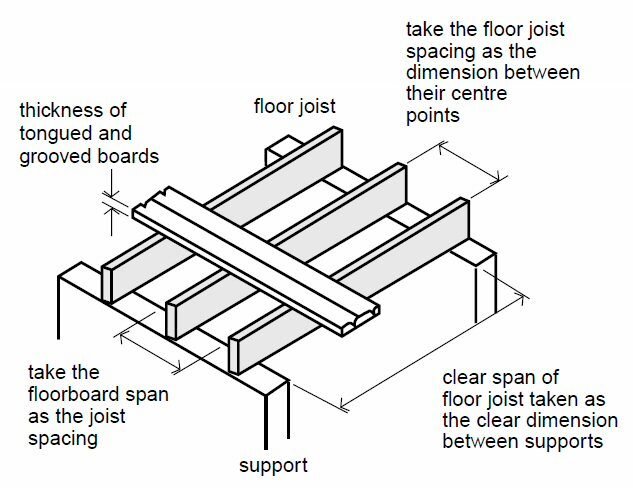

The choice of depth depends largely on the required span, load conditions, and spacing between joists.

What Are the Common Lengths I Joists Available?

I-joists are typically manufactured in standard lengths ranging from 20 feet to 40 feet. The most commonly available lengths for residential use are 24, 28, 32, and 36 feet.

These lengths are designed to minimize waste and simplify installation on-site. Builders can cut I-joists to exact specifications within manufacturer guidelines, but it’s critical not to alter their structural integrity by improperly modifying flanges or webs.

Safeway Piling and Construction offers I-joists in standard lengths from 20 to 40 feet, with custom lengths available to suit your project needs. Their flexible options ensure efficient, high-quality support for both residential and commercial structures.

Are There Standard Sizes for I-joists Used in Commercial Buildings?

Yes, I-joists used in commercial construction are available in larger and more robust sizes compared to residential grades. The depths for commercial I-joists may extend up to 24 inches or more, and flange sizes are typically wider and thicker to accommodate higher load demands. These joists are used in applications like office buildings, schools, or light industrial spaces where longer spans and heavier loads are common.

Additionally, commercial I-joists often come with stricter design standards, additional fire resistance, and enhanced stiffness requirements. Custom design consultation is frequently part of the planning phase for commercial structures.

How Do I Joist Dimensions Compare to Traditional Solid Wood Joists?

I Joists vs. Solid Wood Joists

| Feature | I-Joists | Solid Wood Joists |

| Material | Engineered wood | Natural solid lumber |

| Span Capability | Longer spans | Shorter spans |

| Weight | Lightweight | Heavier |

| Customization | Highly customizable | Limited sizing options |

| Cost | More expensive per unit, but less waste | Usually cheaper upfront |

| Ease of Installation | Precise, but needs careful handling | Easier to work with on-site |

Which Is Better?

- Residential Buildings:

✅ I-Joists are generally better. They allow for longer spans, fewer support beams, and more open floor plans. They’re also more stable over time. - Commercial Buildings:

✅ I-Joists are preferred. They can be engineered for heavy loads and long spans, and customized for fire resistance and performance standards

Can I Joist Dimensions for Specific Structural Needs?

Absolutely. While standard sizes cover most applications, I-joist manufacturers offer custom fabrication for projects with unique structural requirements. Custom options may include tailored depths, flange sizes, or lengths exceeding 40 feet. Engineers can specify I-joists to accommodate unusual spans, heavier loads, or integration with other systems like steel beams and mechanical ducting.

However, custom I-joists must always conform to building codes and be approved by structural engineers to ensure safety and performance. Safeway Piling and Construction can customize I-joist dimensions to fit almost any structural challenge, making them a reliable partner for tailored building solutions.

How Does the Width of an I Joist Affect Its Load-Bearing Capacity?

The width of an I-joist, typically referring to the width of the flange, directly affects its ability to resist bending and distribute loads.

Wider flanges offer a greater surface area for load distribution and increase the moment of inertia, a property that enhances bending resistance. This means that an I-joist with a wider flange can typically carry heavier loads or span greater distances than one with a narrower flange, assuming other dimensions and materials remain constant.

However, it’s not only about load capacity. Wider flanges also make it easier to install flooring materials and reduce the likelihood of subfloor deflection or squeaking over time.

What Are the Minimum and Maximum Depths of I-Joists Used in Floor Systems?

The depth of an I-joist plays a critical role in determining its span and load capacity. Builders commonly use depths ranging from 9-1/2 inches to 16 inches for residential floor systems. However, depending on the specific application and design requirements, they may also use depths as shallow as 5-1/2 inches or as deep as 24 inches.

Contractors typically choose minimum depths for short spans and light loads, such as small residential rooms or decks. For longer spans or heavy-load areas—like open-concept living spaces or commercial buildings—they opt for maximum depths. Engineers determine the ideal joist depth by calculating span length, load type, and compliance with building codes.

What Tools Are Used to Measure and Verify I Joist Dimensions On-Site?

Accurate measurement of I-joist dimensions during construction is crucial for ensuring structural integrity and compliance with design specifications. Common tools used on-site include:

- Tape measures: For quick checks of length, depth, and spacing.

- Calipers: To measure flange width and web thickness precisely.

- Laser distance measurers: For long-span verification.

- Plumb bobs and levels: To ensure proper vertical and horizontal alignment.

Safeway Piling and Construction emphasizes accuracy and attention to detail, using these tools to minimize installation errors and ensure that all I-joists meet engineering and code standards. Our commitment to quality control contributes to safe, efficient, and durable construction outcomes.

How Does the Flange Size Affect I Joist Dimensions and Strength?

Flange size—specifically its width and thickness—has a significant influence on the overall strength and stiffness of an I-joist. Larger flanges increase the joist’s ability to resist bending and twisting under load, improving structural stability. Flange material also affects performance.

For instance, an I-joist with a 3.5-inch-wide LVL flange will outperform a 1.5-inch-wide solid sawn flange in both load capacity and durability. However, larger flanges also increase the cost and weight of the joist, so design efficiency is key.

Are There Code Requirements Related to I Joist Dimensions?

Yes, I-joist dimensions and their use are governed by building codes and engineering standards. In the United States, the International Residential Code and International Building Code provide guidelines for I-joist sizing, spacing, and installation based on span tables and load requirements.

Codes also mandate fire protection measures for I-joists used in floor systems, especially when they support habitable spaces. Additionally, local jurisdictions may have supplementary rules, so engineers and builders must ensure compliance with both national and local codes.

Safeway Piling and Construction ensures full compliance with these standards, delivering safe, reliable, and code-approved installations on every project.

How Do Manufacturers Label or Denote I-Joist Sizes?

Manufacturers typically use a model number or code that includes key information about the joist’s dimensions and performance characteristics. This label is often stamped or printed on the web or flange and includes:

- Depth

- Flange material

- Flange width

- Series or product line

This information helps builders identify the correct joist for a given application and ensures proper installation according to structural plans.

Conclusion of I Joist Dimensions

I-joist dimensions are critical for the safety, stability, and longevity of any floor or roof system. From flange size and joist depth to proper on-site measurements, every detail matters in engineered wood construction. At Safeway Piling and Construction, precision and quality control are at the core of their process. Safeway uses advanced measurement tools and strictly follows building codes and manufacturer specifications to install each I-joist accurately and ensure optimal performance. Whether for residential, commercial, or industrial projects, their expert handling of I-joist dimensions guarantees reliable structural outcomes and long-term peace of mind for builders and property owners alike.