Vibro Hammer for Sheet Pile Driving: The Ultimate Tool for Deep Foundation

Vibro hammer for sheet pile driving is the ultimate tool for fast, efficient, and reliable deep foundation and piling projects.

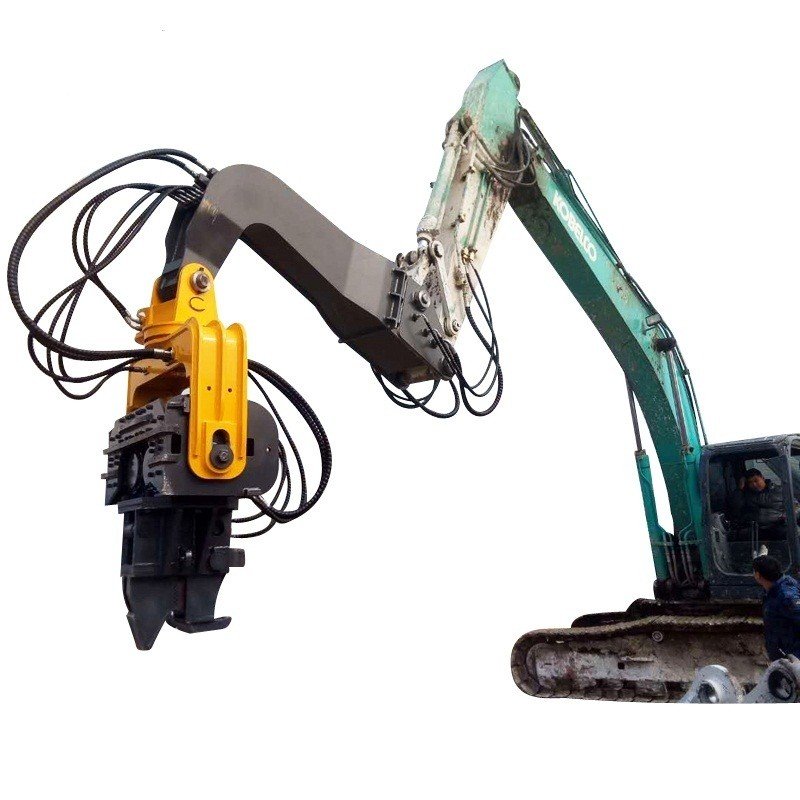

A vibro hammer, also known as a vibratory hammer, is a machine used to drive or extract sheet piles into the ground by generating rapid vertical vibrations.

Unlike impact hammers, vibro hammers use high-frequency vibrations to reduce soil resistance, helping piles penetrate smoothly. The vibrations briefly liquefy the soil, cut friction, and speed up pile insertion or removal with less force.

What are the Main Components of a Vibro Hammer for Sheet Pile Driving?

A vibro hammer consists of several key components that work together to ensure effective sheet pile installation:

- Eccentric Weight System: This is the core of the vibration mechanism. Rotating counterweights create an oscillating motion that transmits vertical vibrations to the pile.

- Clamp or Jaw Assembly: The clamp securely grips the sheet pile during driving or extraction. Hydraulic or mechanical systems often control the grip.

- Vibration Suppressor: This component reduces the transmission of vibrations to the crane or carrier, enhancing safety and comfort for operators.

- Hydraulic Power Pack: Typically located on the ground, this unit powers the vibro hammer through hydraulic pressure.

- Leader or Crane Support: Vibro hammers are mounted on cranes or excavators that provide vertical alignment and lifting support during operation.

Safeway Piling and Construction uses modern vibro hammers with advanced controls to maximize efficiency and safety.

What are the Advantages of Using a Vibro Hammer for Sheet Pile Driving Installation?

Using a vibro hammer offers numerous benefits in both performance and project management:

- Speed and Efficiency: Vibro hammers can install sheet piles faster than conventional impact hammers, leading to shorter project timelines.

- Reduced Noise and Vibration: They generate significantly less noise and ground vibration, making them ideal for use in sensitive urban or residential environments.

- Precision Placement: Operators have better control over pile positioning, ensuring accurate and consistent installation.

- Lower Fuel Consumption: Vibro hammers generally consume less energy per pile compared to traditional driving methods.

- Versatility: Suitable for both driving and extracting sheet piles, increasing the tool’s utility on construction sites.

Vibro hammer vs. impact hammer: Which is more efficient for sheet piling?

When comparing a vibro hammer to an impact hammer, several factors come into play. Impact hammers operate by delivering repeated heavy blows to drive piles, which is effective in dense, cohesive soils like clay. However, they are often slower, noisier, and can cause structural damage to nearby buildings due to high-impact shock waves.

In contrast, vibro hammers are much more efficient in granular soils, such as sand and gravel. They allow for faster installation with minimal disturbance, especially in environmentally sensitive or densely populated areas. Although vibro hammers may struggle in very stiff or cohesive soils, their overall speed and environmental advantages often make them the preferred choice.

At Safeway Piling and Construction, we often recommend vibro hammers for projects in sensitive areas or where speed is a priority.

What Types of Sheet Piles Can Be Driven Using a Vibro Hammer?

Vibro hammers are compatible with a wide range of sheet pile materials and profiles, including:

- Steel Sheet Piles U-shaped, Z-shaped, and straight web

- Vinyl and Plastic Sheet Piles for lighter applications

- H-beams and Tubular Piles

- Temporary Sheet Piles for excavation support

At Safeway Piling and Construction, we match each vibro hammer to the pile’s type and size for the best results.

Under which soil conditions are vibro hammers less effective or unsuitable?

Vibro hammers struggle in dense clay, hardpan, or rock where soil cohesion is high. In these cases, vibration alone isn’t enough. We use impact hammers or pre-drilling to drive piles to the required depth.

Vibro Hammers: Power, Frequency, Safety & Innovation

Vibro hammers are fast, quiet, and eco-friendly tools for sheet pile driving. We use advanced models to install and extract piles with precision. This article covers key features like frequency, power, safety, and recent tech upgrades.

What is the standard frequency and amplitude of a vibro hammer during operation?

Most vibro hammers run at 1,200–2,500 vpm. High frequencies work well in sand and gravel; low ones suit heavier piles or soft clay.

Amplitude, the vertical movement, ranges from 5–15 mm. Higher amplitudes deliver more force for dense soils.

We adjust both settings to match site conditions and ensure efficient, safe piling every time.

How are vibro hammers powered on modern construction sites?

Vibro hammers are typically hydraulically powered, meaning they are connected to a hydraulic power pack via high-pressure hoses. The power pack is usually driven by a diesel engine, though electric-powered units are becoming more common, especially in urban or environmentally sensitive areas where noise and emissions must be minimized.

The hydraulic system powers the rotation of eccentric weights inside the hammer, generating the vertical vibrations required for pile driving. This method provides consistent power, precise control, and compatibility with various carriers like cranes or excavators.

What safety precautions must be followed when using vibro hammers for piling work?

Safety is paramount in any construction environment, and operating a vibro hammer involves several specific precautions:

- Operator Training: Only trained and certified personnel should operate vibro hammers to ensure safe and efficient use.

-

Inspect Equipment Regularly: Check all components frequently for signs of wear, loose connections, and hydraulic leaks to ensure safe operation.

-

Clap the Pile Securely: Always secure the pile firmly before activating the equipment to prevent accidental release or misalignment.

- Area Clearance: Keep a safe perimeter around the operating area to protect workers from vibrations, noise, or falling objects.

- Proper PPE: All personnel should wear personal protective equipment such as helmets, gloves, hearing protection, and high-visibility clothing.

- Vibration Monitoring: In sensitive areas, monitor ground vibrations to avoid structural damage to nearby buildings or underground utilities.

At Safeway Piling and Construction, we strictly follow safety standards. Daily briefings keep our team aligned and prepared.

Can vibro hammers be used for both driving and extracting sheet piles?

Yes, vibro hammers drive and extract sheet piles. By reversing vibration and applying upward force, they loosen soil for smooth removal.

This dual function makes vibro hammers ideal for temporary structures like cofferdams, retaining walls, and excavation supports.

What is the typical depth achievable when installing sheet piles with a vibro hammer?

Typical depths range from 15 to 30 meters (50 to 100 feet), depending on soil, pile type, hammer size, and frequency.

In good soil with strong equipment, deeper drives are possible. In hard soils or rock, we may add pre-drilling to reach the target depth.

How has vibro hammer technology advanced in recent years for better performance and eco-efficiency?

Vibro hammer technology has made significant advancements in recent years, focusing on efficiency, noise reduction, and environmental impact. Some key developments include:

- Quieter Operation: Modern vibro hammers incorporate vibration-damping and soundproofing features, making them suitable for use in populated areas.

-

Use Electric Models to Cut Emissions: Electric-powered vibro hammers actively reduce carbon emissions and lower fuel costs on job sites.

-

Operate with Smart Controls: Digital interfaces give operators real-time performance data, let them fine-tune frequency and amplitude, and improve driving precision.

- Choose Modular Designs for Flexibility: Newer models simplify maintenance and work seamlessly with different machines, boosting efficiency and adaptability.

- Eco-Friendly Fluids: Many hydraulic systems now use biodegradable fluids, minimizing environmental risk in case of leaks.

These innovations align with Safeway Piling and Construction’s commitment to sustainable construction practices and delivering high-quality results with minimal environmental impact.

Conclusion

At Safeway Piling and Construction, we use vibro hammers to ensure fast, safe, and eco-friendly sheet pile driving. Vibro hammers provide quick, reliable installation and extraction with less noise, minimal ground impact, and flexibility for any site.

Our modern equipment drives sheet piles with precision, whether in tight urban spaces or coastal zones. As standards rise, we stay ahead by investing in innovative vibro hammer technology to deliver quality, safety, and sustainability.